Quality Assurance & Analysis

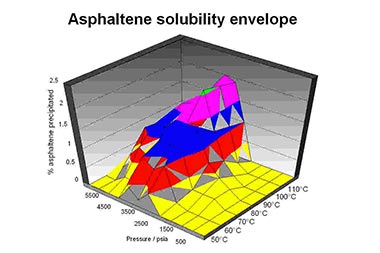

Production chemicals are essential to efficient oil and gas production and processing, but they must be both cost effective and proven to work under applicable field conditions. Application costs can add up to millions of dollars per year and, if it fails, much more. It is therefore essential that applied production chemicals are shown to be fit for purpose, operate at maximum efficiency and are supported by credible selection and quality assurance testing.

OCTL can work alongside a preferred process chemicals supplier to help select and validate chemicals for optimum field production. In addition, as a production chemistry specialist experienced in a wide range of field developments, OCTL also provides an independent QA service that can ascertain whether prescribed production chemicals are the most suitable.

Our bespoke test methods are well respected within the oil and gas production industry. They are used to objectively and accurately determine product performance and monitor ongoing supply quality. Other analytical quality standards such as API, ISO, ASTM and IP procedures are also routinely used to QA products and materials.

And because we are working independently from the supply company, the laboratory results may lead our technicians and consultants to recommend more suitable chemical additives, application methods or engineered solutions, which may not necessarily be distributed by the preferred supplier.

OCTL also offers an asset specific benchmarking facility to determine the field performance of production chemicals. Working with the field operator, OCTL will develop a series of field performance-based standards to evaluate all production and process chemicals. Products already being used in the production process would be benchmarked to provide a standard performance index that enables the chemical supplier and field management team to rank product performance on an ongoing basis. It also enables allows alternative production or process chemicals to be measured against the same benchmark thus stimulating competition for the most effective field solution.

OCTL offers further independent QA and analytical services to determine the quality and performance of drilling fluids and drilling fluid components. This is largely conducted to API and ISO standards but other in-house and industry methods can also be applied to check product quality and field performance.

Sitemap

- Home

- Consultancy Services

- Chemical Management

- Training

- Material Selection / Corrosion Management

- Field Chemistry Reviews

- Drilling, Completion and Well Stimulation

- Project Management

- Lab Services

- Production Chemistry

- Flow Assurance

- Well Productivity

- Analysis and QA Services

- R&D

- Contact Us

- About Us

- Clients + Projects

- Careers

- Equipment Sale